announcement

Conflict Minerals Policy of New Heart Technology Co., Ltd.

The conflict minerals refer to those especially tin, gold, tantalum, tungsten, cobalt and mica mined from Democratic Republic of the Congo or its adjacent areas with illegal military conflicts under the circumstances of violation of human rights. The mineral extractions in these areas are carried out through force labor of civilians under poor working conditions, violating human rights of the civilians. Thus New Heart Technology Co., Ltd. requires the suppliers to provide a Conflict Mineral Policy Statement & CFSP to demonstrate the metals used in their products are not from the areas with illegal military conflicts in accordance with Electronic Industry Code of Conduct (EICC) and Conflict-Free Smelter Program (CFPS). New Heart Technology Co., Ltd. will conduct relevant managements continuously to support our Conflict Minerals Policy and maintain our social responsibility of not using the conflict minerals.

Nov 2022 To install keysight E5063A ENA Vector Network Analyzer

May 2022 To install SCREEN Direct Imaging System Ledia 6S-M

Mar 2022 To install GRETECH Vacuum Plugging Machine VCP500-1

Oct 2021 To install ATG A9 Flying probe tester

May 2021 To install HITEC Instant video Measuring Machine CZW-43

Oct 2019 Attained IATF 16949:2016 Certificate

May 2019 To install 2 Spindle drilling machine

Apr 2019 To install Fischerscope X-ray Xulm-240

Oct 2018 Attained ISO 9001:2015 Certificate

Mar 2018 To implement automatic Ucamco software

Jan 2018 To install Hot melt machine

Jul 2017 To install Automated Visual Inspect

Feb 2017 To install Automated Optical Inspection.

Feb 2016 To install Laser photogenerator laser photoplotter

Dec 2015 To install Auto Exposure CCD Machine.

May 2015 To install automatic ink jet printer

Jan 2015 To implement automatic Pre-CAM,Ezcam,Ezplan software

Nov 2014 To install high-speed flying probe tester A8

May 2013 To install two high-speed spindle X-ray compensated drilling Machine.

Sep 2012 To install semi-auto Collimated UV Exposure Machine.

Jun 2011 To install PCB Rounting Machine.

May 2011 To implement to the ERP System

Aug 2010 To install Vacuum Plugging Machine.

Aug 2010 Expansion of Engineering Department at Huanbei Road Zhongli City of Taoyuan County

Sep 2009 Attained ISO 9001:2008 Certificate.

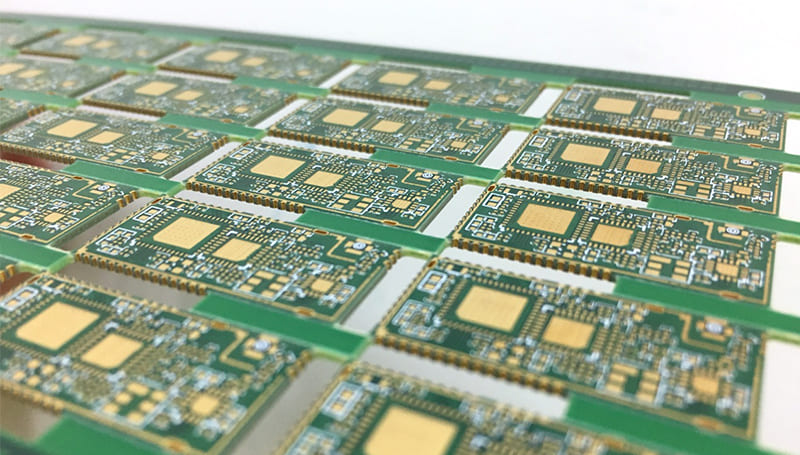

Jul 2009 Succeed in developments of high-end processes including HDI,semi-hole,via in pad,etc.

May 2009 Plant moved to the present address,NO.11,Minzhu Road,Dayuan industrial Park in Dayuan Township of taoyuan County.

Sep 2008 Enhancement of QA System and installations of Flying Probe Tester,optical inspection instrument,3D Measurement machine,etc.

Jan 2008 To implement of on-line electronic ratification system(Core Press).

Jun 2007 Attained UL Certificate

Mar 2007 Attained ISO 9001:2000 Certificate

Sep 2005 Successful development of 36-layer PCB

Feb 2005 To implement TDR-2004 testing software.

Apr 2004 To implement automatic IGI ParCAM software

Apr 2003 Successful development of aspect ratio production technology

Aug 2002 Successful development of Blind Buried Hole Technology

May 2001 Moved plant to Sec.1 of Nanshan Road, Luzhu Township of Taoyuan County for expanding productivity.

Jul 1998 Establishment of company at Nanshang Road, Luzhu Township of Taoyuan County

繁體中文

繁體中文